SHINHAN CS Co.,Ltd.

Creative skills and values

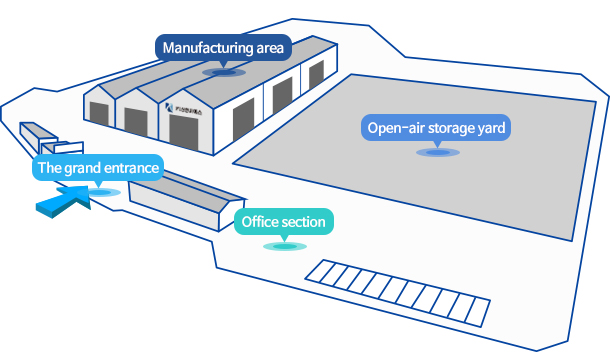

Factory introduction

We will reciprocate the favor of our customers with highest quality based on the latest production facilities and strict quality assurance system.

SHINHAN CS has the factory, built in 2017 and furnished with the latest facilities, which is located in Judeok Agriculture and industry Complex and specializes in the manufacture of deck plates. We have built the stable production system with the latest production equipment and introduced the multi-stage inspection system and quality assurance and control system which has created a solid foundation for us to provide the highest quality products and evolve into the nation's largest manufacturing plant. SHINHAN CS will make constant efforts to transform itself into a global company based on relentless technological innovation, R&D, expansion of production facilities.

Factory introduction

Basic Status

- 2017. 03 Established SHINHAN CS Co., Ltd.

- 2017. 10 Completed the deck plate factory

Factory size

- 7000m2

- Office section(1), manufacture section(3), open-air storage yard, etc.

Prime product

- Smart deck / Variable Removal deck / SH insulation deck / Strong Deck, etc.

View of inside and outside

Specifications of major production facilities

| Facilities name | Productive capacity | Introduction year | Memo |

|---|---|---|---|

| DRAWING M/C (Round steel wire ) |

Finishing Wire Speed: max 370m/min | 2017.09 |

|

| DRAWING M/C (Circular steel wire ) |

Finishing Wire Speed: max 400m/min | 2017.09 |

|

| TRUSS GIRDER WELDING M/C | Max Working Speed: 36m/min upper.lower chord:7~16mm LATTICE:5~6mm |

2017.09 |

|

| FORMING M/C | Line speed: 20(18)m/min | 2017.09 |

|

| DECK PLATE WELDING M/C | CAPA: 5m/min, Thickneas:0.5t | 2017.09 |

|